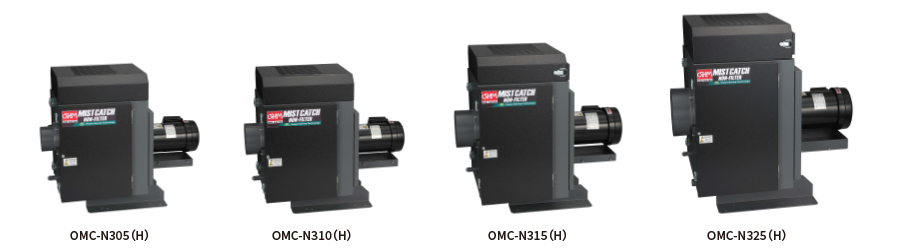

Non-filter oil mist collector OMC-N3 series

Industry top energy saving and high collection efficiency as Non-Filter!

Small and light weight design makes maintenance work easy.

Small and light weight design makes maintenance work easy.

Features

| Type | Specifications | |||

| Non-filter | Energy saving | High collection rate | Small and light weight | Max. suction air temp. 80℃ |

Certificates/Approvals

| EU RoHS2 | China RoHS | CE* | UL | CSA | PSE |

Remark (*): Excluding OMC-N305(H)

Model/Specifications

| Model | OMC- N305 |

OMC- N305H |

OMC- N310 |

OMC- N310H |

OMC- N315 |

OMC- N315H |

OMC- N325 |

OMC- N325H |

|

| Max. air flow *1 | 4.5/5.0m3/min | 8.0/10.0m3/min | 12.5/15.0m3/min | 20.0/23.0m3/min | |||||

| Max. static pressure *1 | 0.56/0.79kPa | 0.63/0.88kPa | 1.08/1.50kPa | 1.59/2.20kPa | |||||

| Collection efficiency | Min. 99% | Min. 98% | Min. 99% | Min. 98% | Min. 99% | Min. 98% | Min. 99% | Min. 98% | |

| Particle diameter | 2µm or larger | 1µm or larger | 2µm or larger | 1µm or larger | 2µm or larger | 1µm or larger | 2µm or larger | 1µm or larger | |

| Rated voltage | 3-phase, 200VAC 50Hz/ 200 ‒ 220VAC 60Hz | ||||||||

| Rated motor output | 0.2kW(2P) | 0.4kW(2P) | 0.75kW(2P) | 1.5kW(2P) | |||||

| Motor efficiency*2 | - | 76.8/76.8-77.6% | 81.5/81.1-82.5% IE3/IE3-IE3 |

85.8/85.6-86.0% IE3/IE3-IE3 |

|||||

| Rated current consumption *1 | 0.9/0.9-0.9A | 1.4/1.4-1.4A | 2.3/3.0-2.9A | 4.1/5.9-5.6A | |||||

| Max. current consumption *1 | 1.1/1.0-1.0A | 1.9/1.7-1.7A | 4.0/3.9-3.6A | 7.1/7.1-6.4A | |||||

| Working temperature | 0 to +40℃ | ||||||||

| Working humidity | Max. 85%RH, free from condensation | ||||||||

| Noise | 69/72dB(A) | 74/76dB(A) | 76/79dB(A) | ||||||

| Max. suction air temp. | +80℃ | ||||||||

| Conformity | EMC | - | EMI:EN61000-6-4 EMS:EN61000-6-2 | ||||||

| MD | - | EN ISO/12100 EN60204-1 Overvoltage category Ⅱ, Pollution degree 3 | |||||||

| Environment | RoHS2 | ||||||||

| Suction port diameter | Ø98mm | Ø123mm | Ø148mm | Ø198mm | |||||

| Color | Powder coating : Dark gray(N4 equivalent), Black (N1 equivalent) |

||||||||

| Weight | 25kg | 40kg | 56kg | ||||||

| Drain port | Ø31 pipe | ||||||||

*1. Rated value at the time of the ambient air temperature of 25℃

*2. Efficiency value of the motor unit.

*2. Efficiency value of the motor unit.

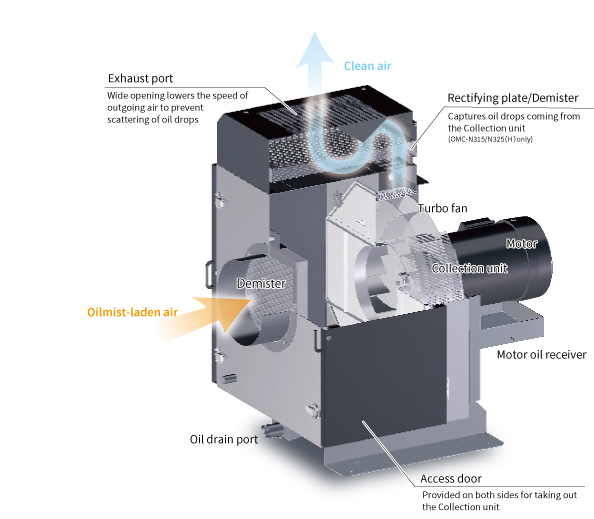

Structure

Completely redesigned structure pursuing the optimum airflow enabled high performance with small energy.

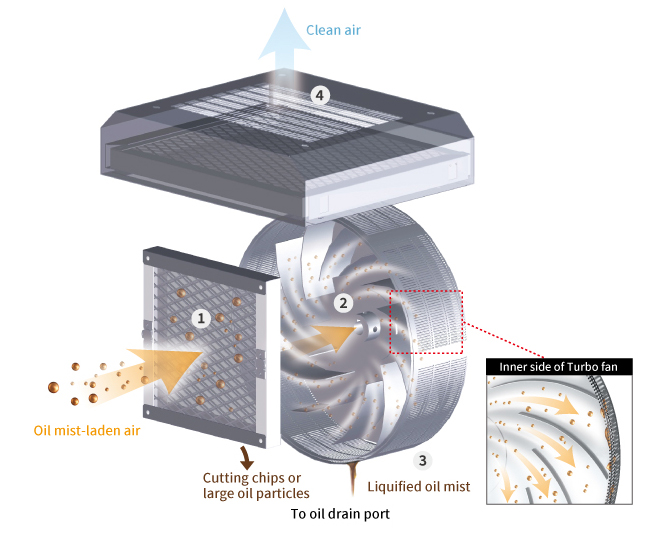

Mechanism

- Cutting dust and large particles in the incoming air are removed at the Demister on suction side.

- Turbo fan accelerates the air speed to blow it in the centrifugal direction and let the oil particles hit against the Collection unit.

- Oil particles caught by the Collection unit are gathered on the inner wall by centrifugal force to be discharged from the drain port in the form of liquid.

- Purified air goes out.

OMC-N3 realizes high collection rate by making more oil particles collide against its Collection unit.

Smaller particles that are likely to escape are captured without fail.

Smaller particles that are likely to escape are captured without fail.

Maintenance

Take out the Collection unit and clean it using an air blow gun or a brush.

Contents of page

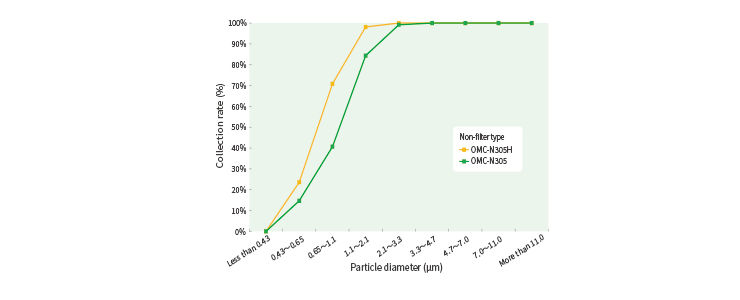

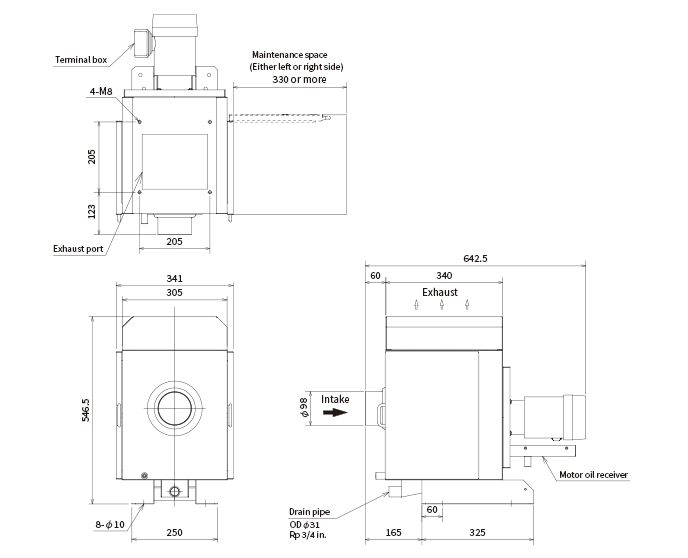

OMC-N305(H)

Max. air flow

4.5/5m3/min

A complete set of supply

Oil Mist Collector: 1 unit Ø32Drain hose: 2m long Drain hose band: 1 pc.

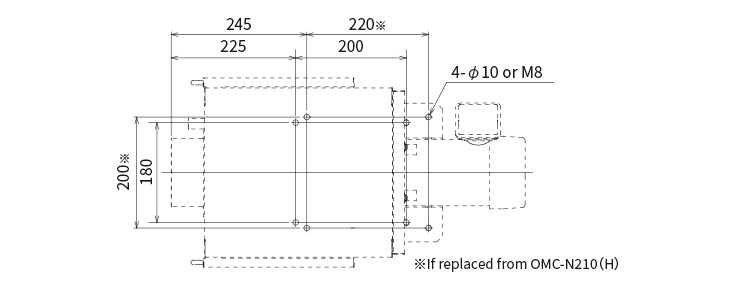

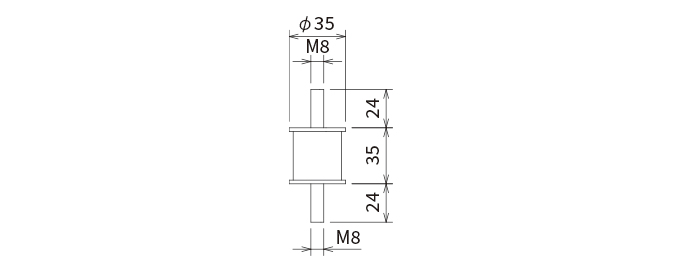

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

Collection efficiency

Test oil : Water-insoluble cutting oil

Measuring instrument : Low volume air sampler type AN-200

Measuring instrument : Low volume air sampler type AN-200

Max. air flow

8/10m3/min

A complete set of supply

Oil Mist Collector : 1 unit Ø32 Drain hose : 2m long Drain hose band : 1 pc.

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

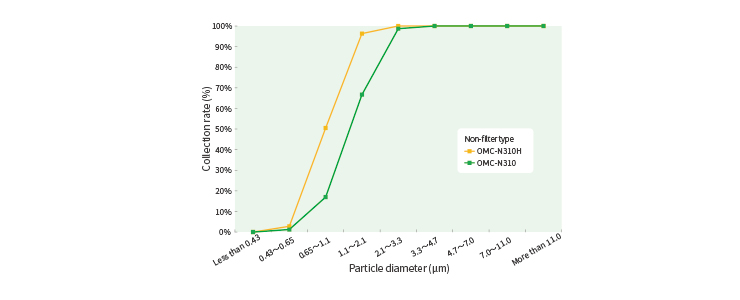

Collection efficiency

Test oil : Water-insoluble cutting oil

Measuring instrument : Low volume air sampler type AN-200

Measuring instrument : Low volume air sampler type AN-200

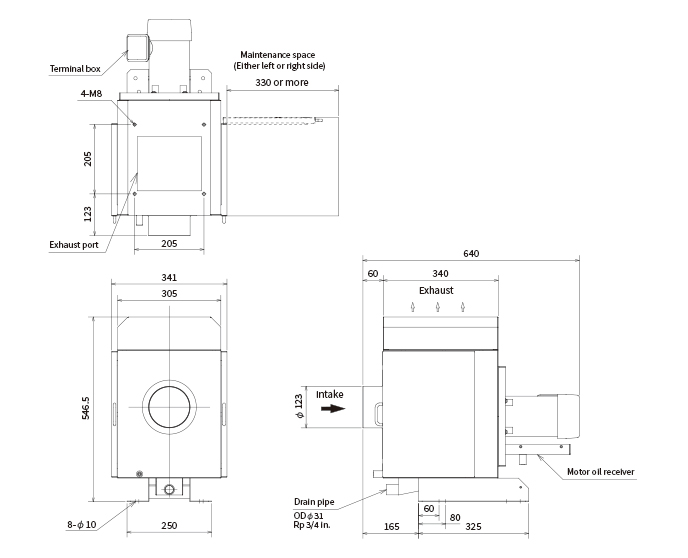

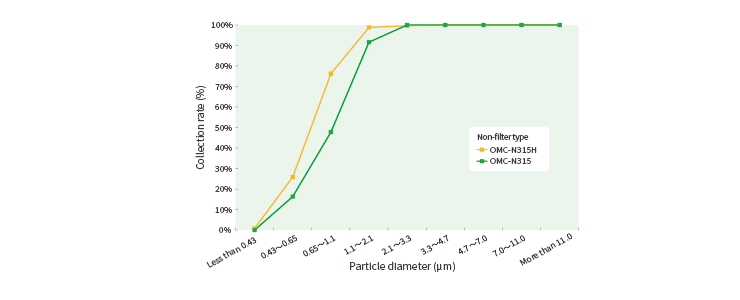

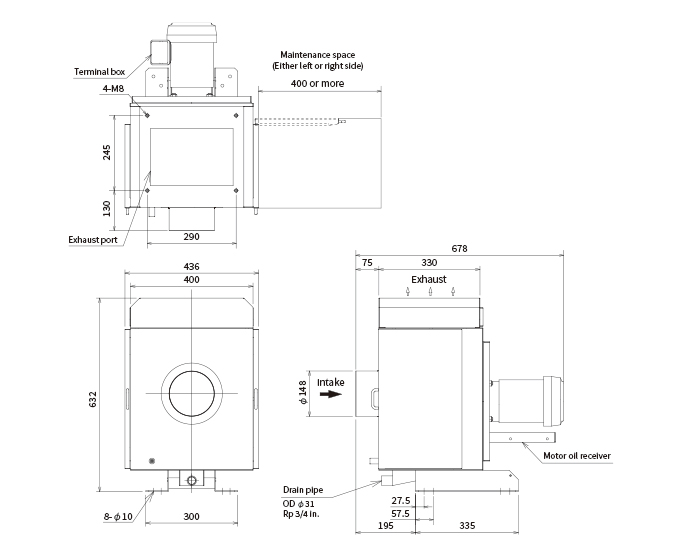

Max. air flow

12/15m3/min

A complete set of supply

Oil Mist Collector : 1 unit Ø32 Drain hose : 2m long Drain hose band : 1 pc.

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

Collection efficiency

Test oil : Water-insoluble cutting oil

Measuring instrument : Low volume air sampler type AN-200

Measuring instrument : Low volume air sampler type AN-200

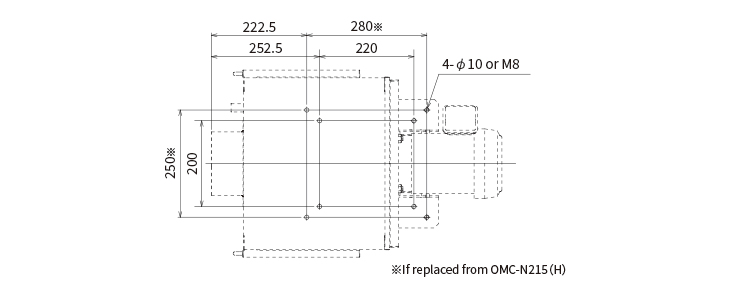

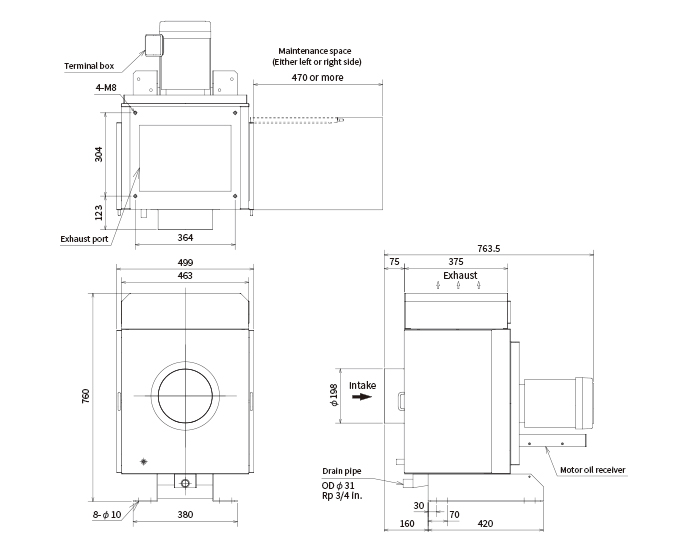

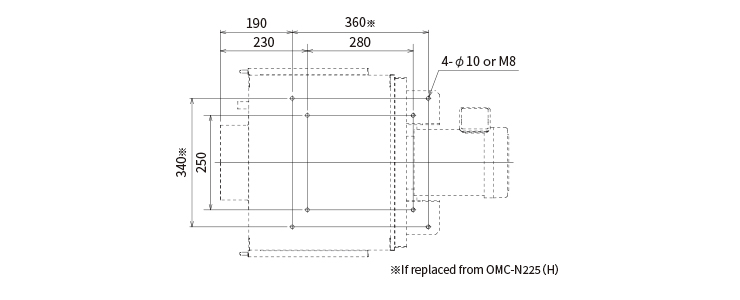

Max. air flow

20/23m3/min

A complete set of supply

Oil Mist Collector : 1 unit Ø32 Drain hose : 2m long Drain hose band : 1 pc.

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

Anti-vibration rubber: 4 pcs. (M8 nut, M8・M8 spring washer and M8 plain washer: 8 sets)

Motor oil receiver: 1 pc. (M4 flange nut: 4 pcs.)

Maintenance sticker: 1 sheet Instruction manual: 1 copy

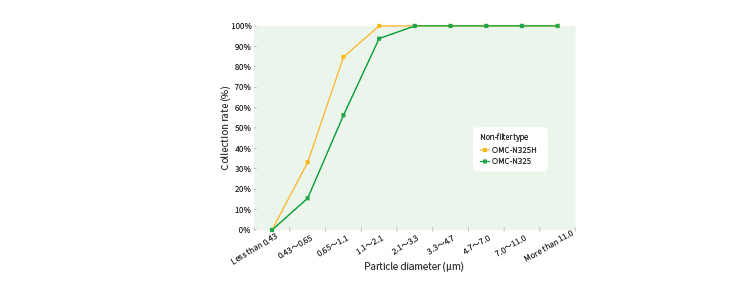

Collection efficiency

Test oil : Water-insoluble cutting oil

Measuring instrument : Low volume air sampler type AN-200

Measuring instrument : Low volume air sampler type AN-200

Cautions

・This product is intended for collecting general watersoluble and oil-based mist that generates in production process by machine tools. Never have it inhale the following substances.

- Ignition sources and fire sparks generated in machine processing,

- Flammable substances such as gasoline, thinner, benzin, kerosene and others as well as oil and cleaning liquid with an ignition point 80 degrees C or below,

- Explosive substances such as aluminium, magnesium and titan as well as materials ridden with those substances,

- Flammable liquid, mist and materials ridden with these substances,

- Corrosive and adhesive substances and hazardous gas or air with a lot of unusual substances

- Large amount of dust or cutting chips

- Hot air exceeding 80 deg. C.

- Large amount of liquid,

- Substances that remarkably accelerate rusting of metals or aging of plastics

・This product should not be used in an atmosphere which contains chlorine, sulfuric or fluorine gasses, oxalic acid, xylene, or methyl tetrachloride and the like.

・Do not use this product in a corrosive atmosphere.

・Tampering or repairing the product should be strictly avoided. Please contact us for repairing service.

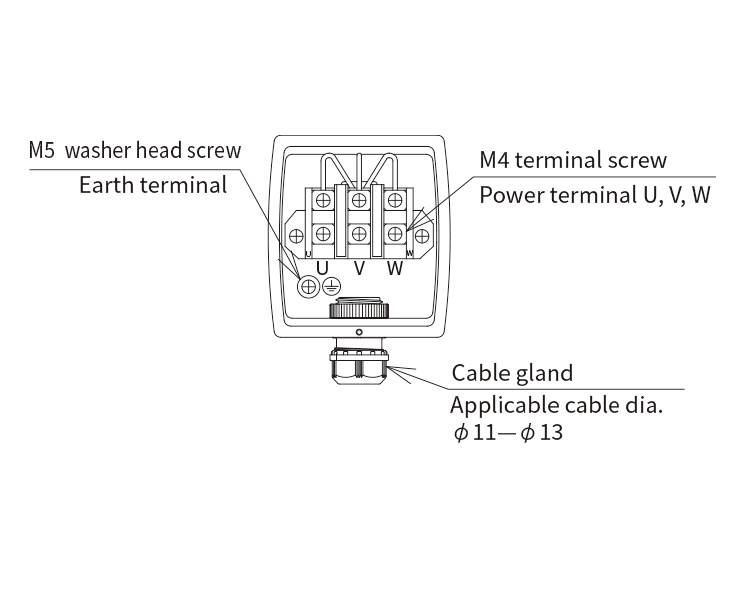

・Do not operate the product with its terminal box uncovered.

・Never touch the motor while the unit is in operation. Do not put your fingers or foreign matters into the rotating part of Turbo Fan.

・Indoor use only. The altitude of the site of use should be lower than 1000 m.

・The site of use should be free from vibration or impact.

・Make sure that the packaging is not damaged on delivery.

・Use this product within the temperature range from 0℃ to +40℃ and humidity not exceeding 85%RH (no condensation).

・Impact, vibration or excess load should be avoided during transportation.

・Precision apparatuses should not be arranged near the exhaust port where fine particles may fall on.

- Ignition sources and fire sparks generated in machine processing,

- Flammable substances such as gasoline, thinner, benzin, kerosene and others as well as oil and cleaning liquid with an ignition point 80 degrees C or below,

- Explosive substances such as aluminium, magnesium and titan as well as materials ridden with those substances,

- Flammable liquid, mist and materials ridden with these substances,

- Corrosive and adhesive substances and hazardous gas or air with a lot of unusual substances

- Large amount of dust or cutting chips

- Hot air exceeding 80 deg. C.

- Large amount of liquid,

- Substances that remarkably accelerate rusting of metals or aging of plastics

・This product should not be used in an atmosphere which contains chlorine, sulfuric or fluorine gasses, oxalic acid, xylene, or methyl tetrachloride and the like.

・Do not use this product in a corrosive atmosphere.

・Tampering or repairing the product should be strictly avoided. Please contact us for repairing service.

・Do not operate the product with its terminal box uncovered.

・Never touch the motor while the unit is in operation. Do not put your fingers or foreign matters into the rotating part of Turbo Fan.

・Indoor use only. The altitude of the site of use should be lower than 1000 m.

・The site of use should be free from vibration or impact.

・Make sure that the packaging is not damaged on delivery.

・Use this product within the temperature range from 0℃ to +40℃ and humidity not exceeding 85%RH (no condensation).

・Impact, vibration or excess load should be avoided during transportation.

・Precision apparatuses should not be arranged near the exhaust port where fine particles may fall on.