Electrostatic oil mist collector OMC-E series

High collection capability by ionizing mist!

Suitable for both oil and water-soluble mists

Suitable for both oil and water-soluble mists

Features

| Type | Specifications | |

| Electrostatic | Energy saving | High collection efficiency |

Certificates/Approvals

| EU RoHS2 | EU RoHS | China RoHS | CE | UL | CSA | PSE |

Model/Specifications

| Model | OMC-E21 | OMC-E310 | OMC-E315 | OMC-E325 | OMC-E345 | |

| Max. air flow *1 | 8/10m3/min | 7/8m3/min | 12/14m3/min | 22/25m3/min | 40/45m3/min | |

| Max. static pressure ※1 | - | 0.68/0.96kPa | 0.86/1.21kPa | |||

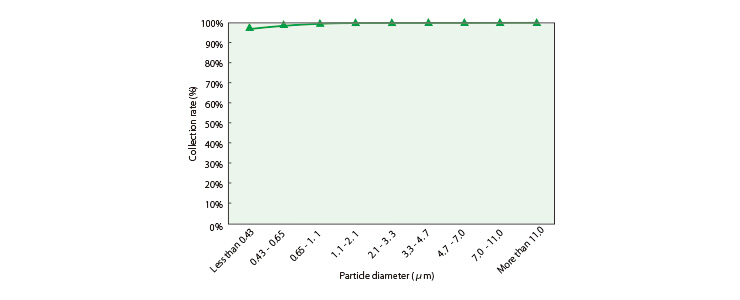

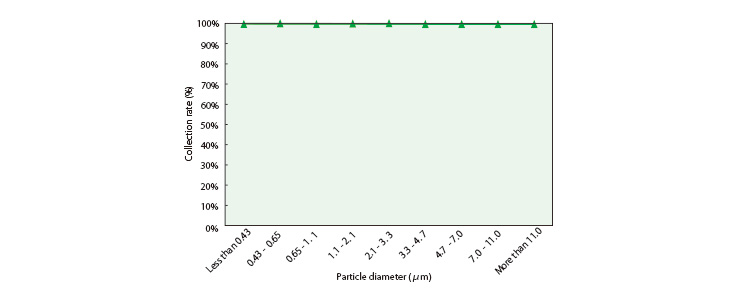

| Collection efficiency | Min. 99% (by gravimetric method) | |||||

| Type of mist collectable | Oil-based and water-soluble | |||||

| Rated voltage | 3-phase, 200 VAC 50/60 Hz | |||||

| Rated motor output | 0.2kW (2P) | 0.2kW(2P) | 0.4kW(2P) | 0.75kW(2P) | 1.5kW(2P) | |

| Motor efficiency*2 | - | 81.5/81.1 IE3/IE3 | 85.8/85.6 IE3/IE3 | |||

| Rated current consumption*1 | 1.7/2.0A or less | 1.3/1.4A or less | 1.7/1.9A or less | 2.5/3.2A or less | 4.2/5.8A or less | |

| Rated power consumption*1 | - | 240/320W or less | 370/540W or less | 590/900W or less | 1090/1730W or less | |

| Working temperature | 0 to +40℃ | |||||

| Working humidity | 10 to 80%RH, free from condensation | |||||

| Noise | 75dB(A) | 74dB(A) | 79dB(A) | 72dB(A) | 75dB(A) | |

| Max. oil mist density | 150mg/m3 | 300mg/m3 | ||||

| Max. suction air temp. | +40℃ | |||||

| Ozone concentration | Less than 0.04 ppm | |||||

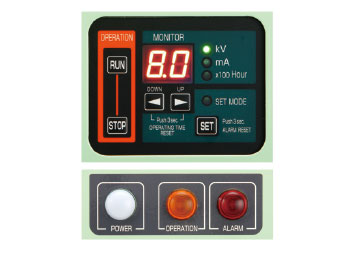

| Display | Power (White) Electrode energization (Orange) Electrode check (Red) |

Power (White) Operation (Orange) Alarm (Red) |

||||

| External input | - | 24VDC Continuous signal | ||||

| External output | Alarm output 1c 250VAC 2A 30VDC 2A |

Alarm output 2c 250VAC 2A 30VDC 2A |

Alarm output 1a (250VAC 2A, 30VDC 2A) ×2 |

|||

| Safety circuit | High voltage cutoff and motor stop in the event of frequent spark discharges, high voltage short circuit and door open | High voltage cutoff and motor stop in the events of freaquent sparking, high voltage short circuit, overcurrent, overcurrent on motor, abnormal heating of high voltage power board or door open |

||||

| Conformity to standards | Environmental standard | RoHS2 | RoHS | |||

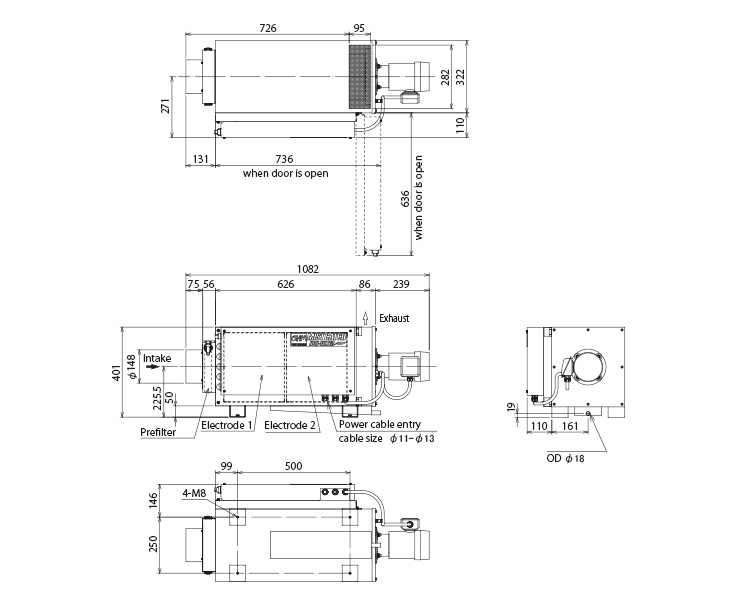

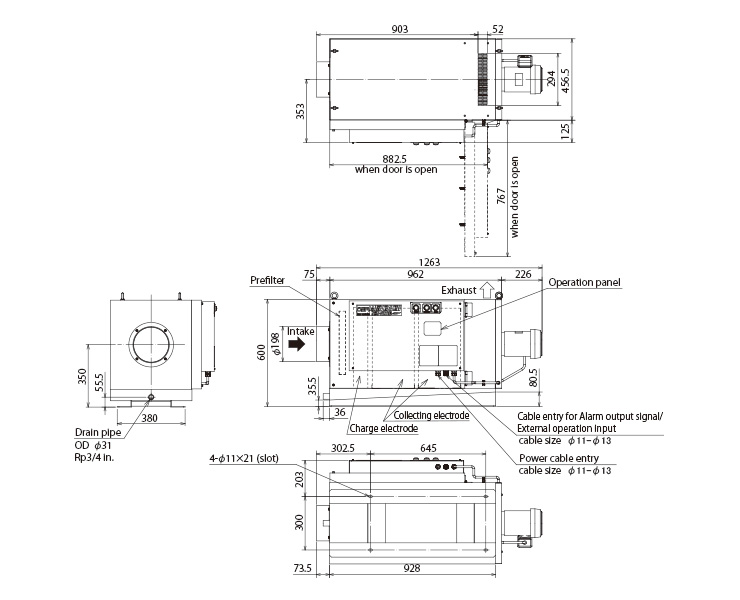

| Suction port diameter | Ø148mm | Ø198mm | Ø200mm at three places | |||

| High voltage output | HV : DC-9kV/-8kV/-7kV LV : DC-6kV/-5kV/-4kV (switchable) |

DC-9kV/-8kV/-7kV (switchable on operation panel) |

||||

| Color | Powder coating, Ivory (10GY9/1 equivalent) and Light green (10GY8/4 equivalent) | |||||

| Weight | 44.0kg | 51.0kg | 52.0kg | 108.0kg | 185.0kg | |

| Drain port | Ø18 pipe | Ø31 pipe | ||||

*1. Rated value at the time of the ambient air temperature of 25℃

*2. Efficiency value of the motor unit.

*2. Efficiency value of the motor unit.

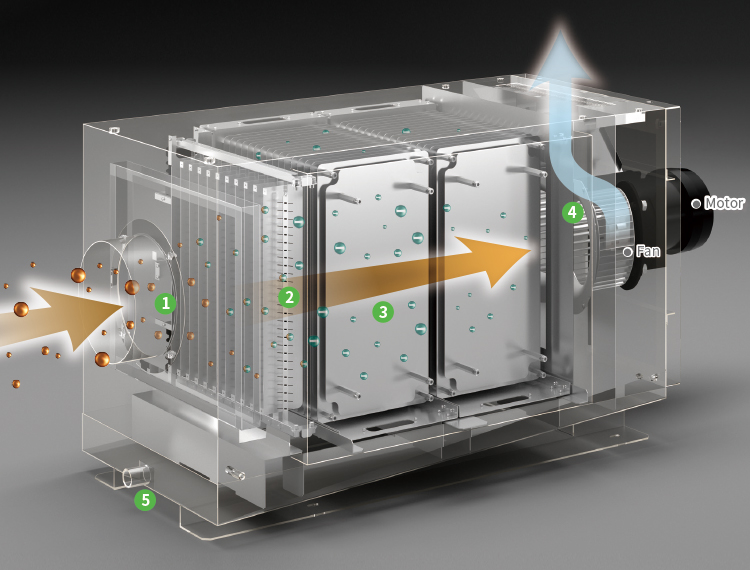

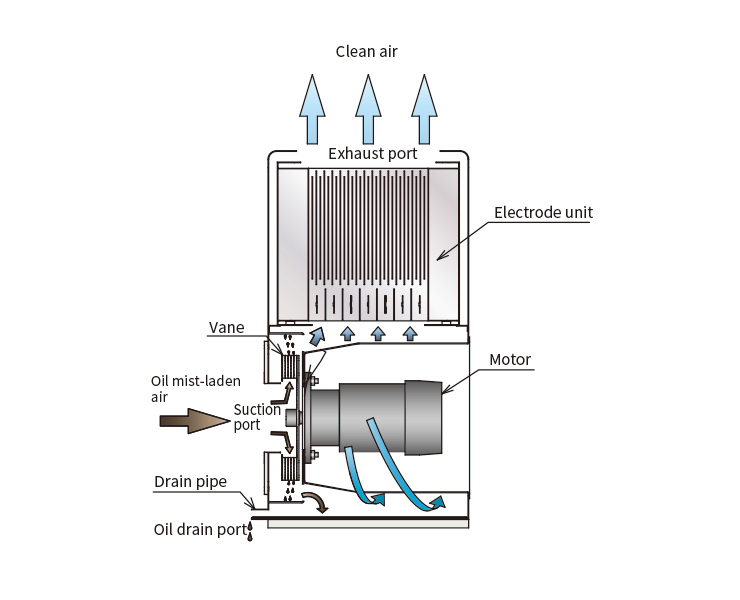

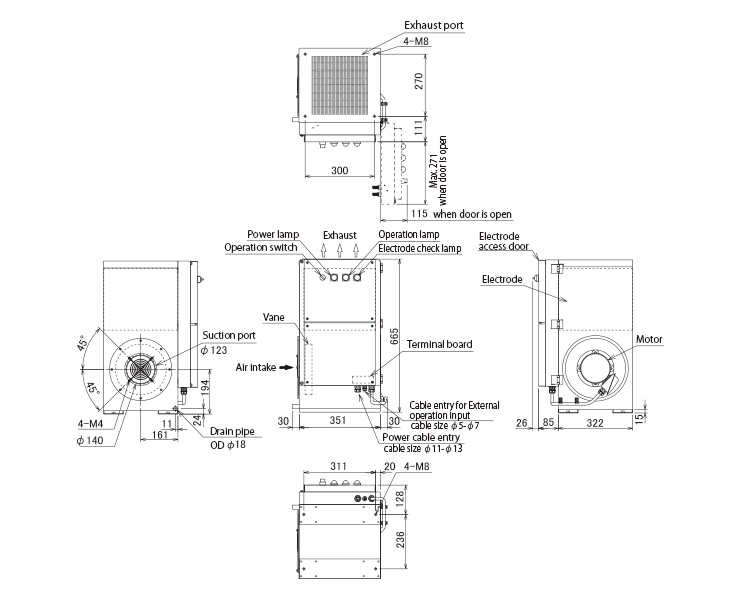

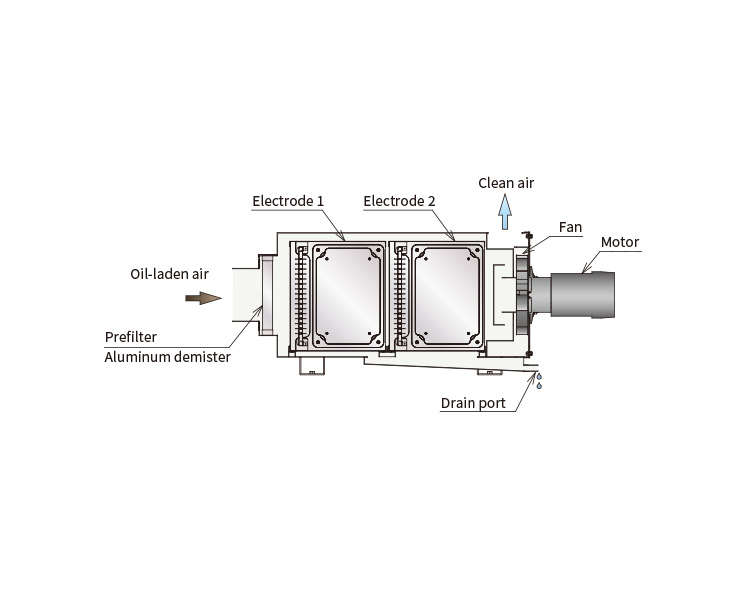

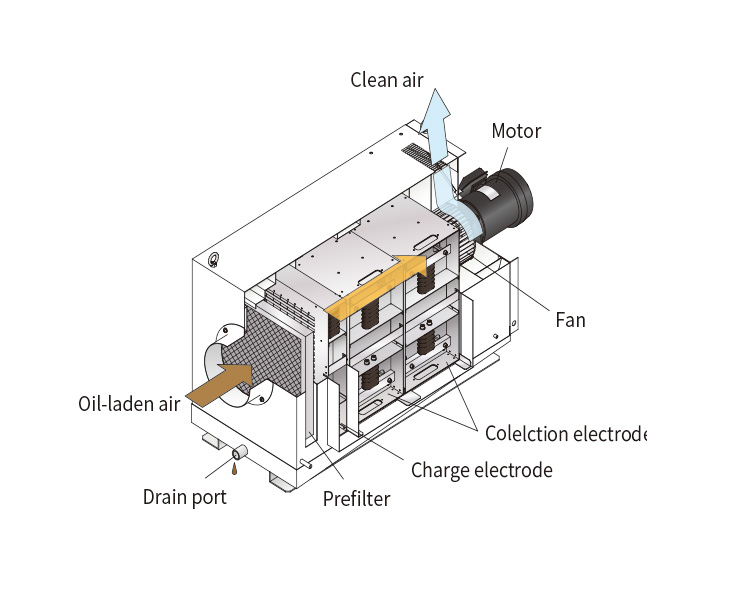

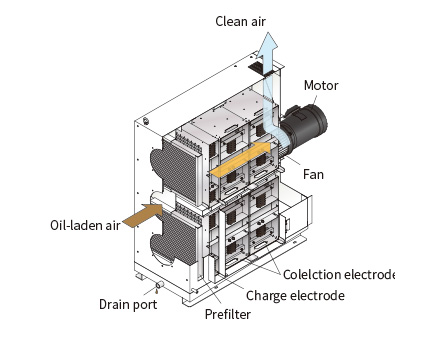

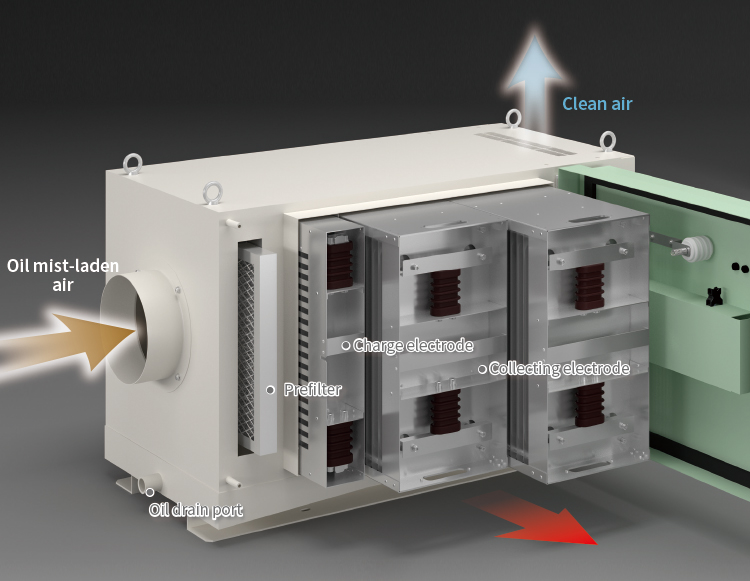

Structure

Original technology achieved suctioning mist at the highest level of concentration

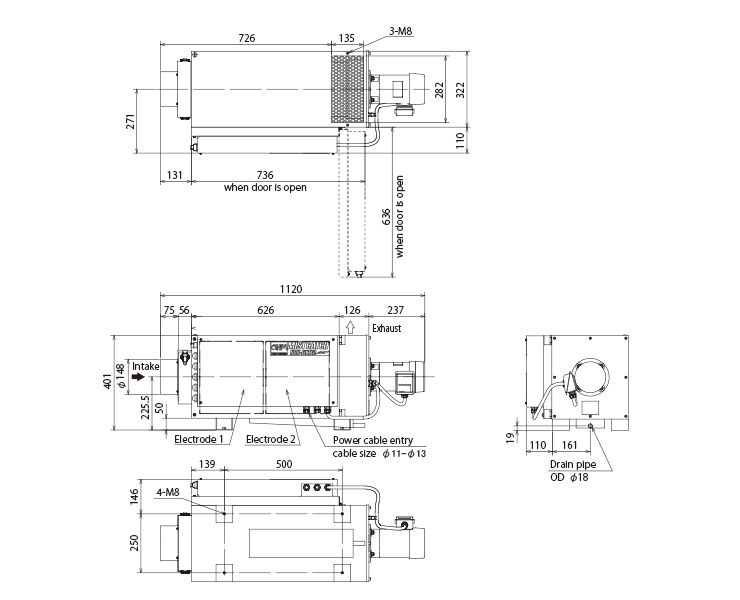

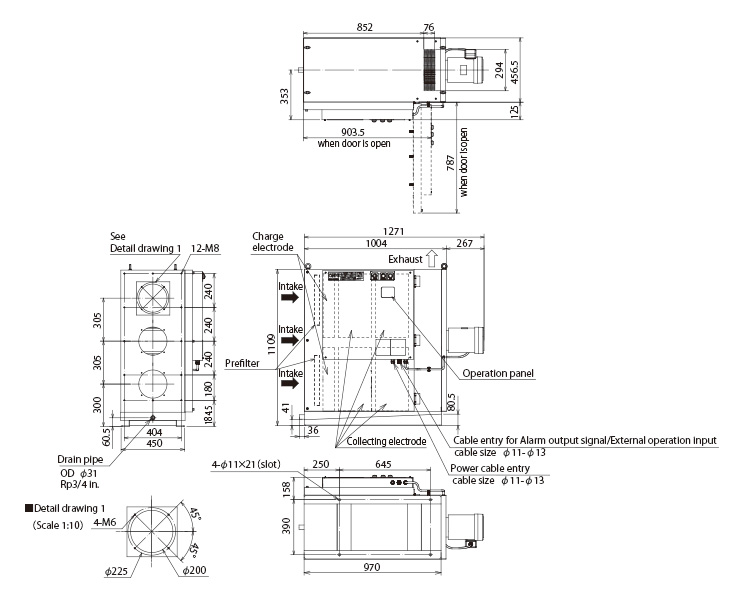

*Illustration below shows OMC-E325. Structural design is different by model.

*Illustration below shows OMC-E325. Structural design is different by model.

Operation panel and lamp

Notifies abnormality and maintenance time by fulfulling monitoring function.

The lamps are readily visible from a distant place.

The lamps are readily visible from a distant place.

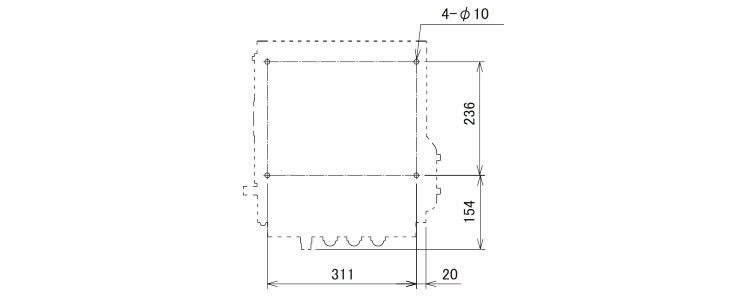

Electrode

Realized light weight by separating charge and collecting electrodes. Each electrode unit has handles which makes detachment easier. Designed for ease of maintenance work.

Rectification plate

Rectification plate guides air to go out straight up, which prevents working people and equipment from being exposed to exhaust air directly.

- Oil mist-laden air passes through the pre-filter and then goes into Charge electrode.

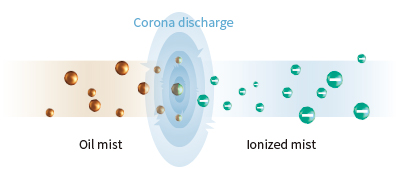

- At Charge electrode, corona discharge occurs between the high-voltage needle electrode and the grounded plate electrode, which causes ionization of oil particles.

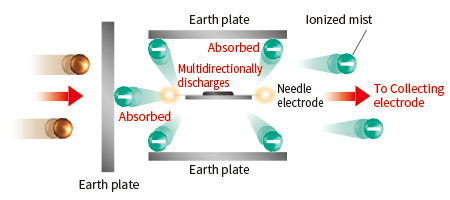

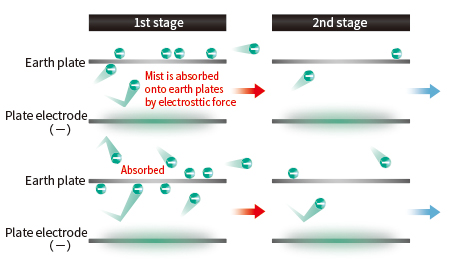

- At Collection electrode, high voltage is applied to the parallel arranged plate electrodes so they absorb the particles that ionized by electrostatic force.

- Particles escaped from the Electrode 1 are collected in the Electrode 2 and purified air is discharged from the fan.

- Collected particles are liquified and then discharged from drain port.

Wide angle-discharge of ion

The uniquely designed needle electrodes realized multidirectional discharge.

This largely expanded discharge area of oil mist.

This largely expanded discharge area of oil mist.

Completely absorbs mist in two step

Enhanced mist absorption rate by enlarging plate surface area of collection electrode. In addition, 2-step collection system does not allow mist to escape. Amazingly high collection rate and mist concentration rate have been achieved.

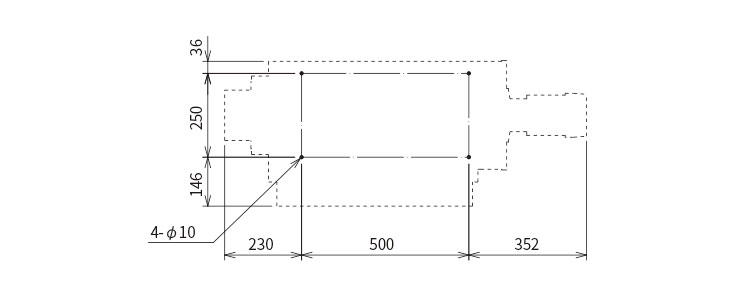

OMC-E21

Max. air flow

8/10m3/min

Max. mist concentration inhalable

150mg/m3

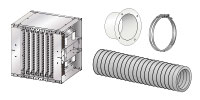

A complete set of supply

Oil Mist Collector : 1 unit Drain hose : 2m long Drain hose band : 1 pc.

Instruction manual : 1 copy

Instruction manual : 1 copy

Max. air flow

7/8m3/min

Max. mist concentration inhalable

300mg/m3

A complete set of supply

Oil Mist Collector : 1 unit Drain hose : 2m long Drain hose band : 1 pc.

Instruction manual : 1 copy

Instruction manual : 1 copy

Max. air flow

12/14m3/min

Max. mist concentration inhalable

300mg/m3

A complete set of supply

Oil Mist Collector : 1 unit Drain hose : 2m long Drain hose band : 1 pc.

Instruction manual : 1 copy

Instruction manual : 1 copy

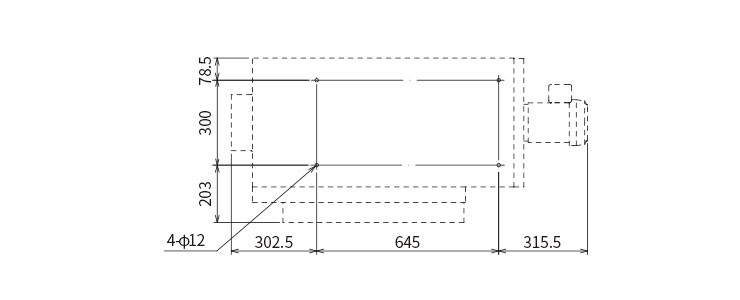

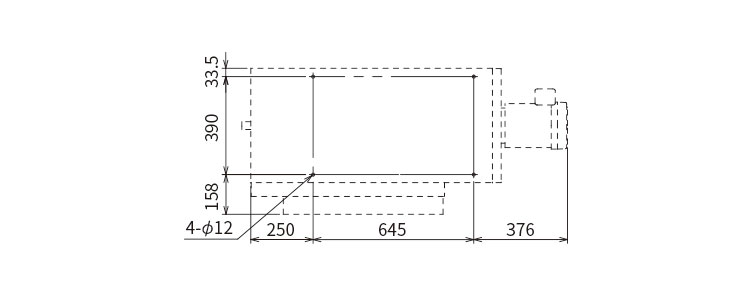

Max. air flow

22/25m3/min

Max. mist concentration inhalable

300mg/m3

A complete set of supply

Oil Mist Collector : 1 unit Drain hose : 2m long Drain hose band : 1 pc.

Instruction manual : 1 copy

Instruction manual : 1 copy

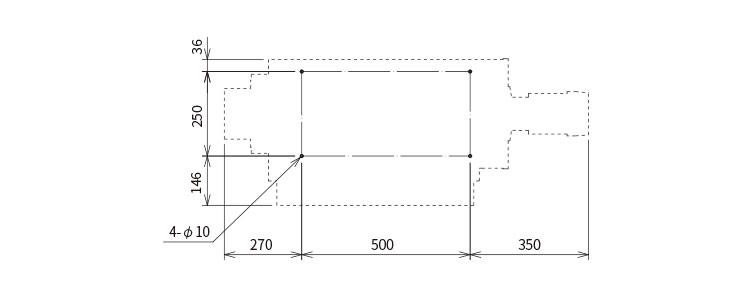

Max. air flow

40/45m3/min

Max. mist concentration inhalable

300mg/m3

A complete set of supply

Oil Mist Collector : 1 unit Drain hose : 2m long Drain hose band : 1 pc.

Instruction manual : 1 copy

Instruction manual : 1 copy

Cautions

・This product is intended for collecting general watersoluble and oil mist that generates during production process using various machine tools. Never have it inhale the following substances.

- Ignition sources and fire sparks generated in machine processing,

- Flammable substances such as gasoline, thinner, benzin, kerosene and others as well as oil and cleaning liquid with an ignition point 80 degrees C or below,

- Explosive substances such as aluminium, magnesium and titan as well as materials ridden with those substances,

- Flammable liquid, mist and materials ridden with these substances,

- Corrosive and adhesive substances and hazardous gas or air with a lot of unusual substances

- Large amount of dust or cutting chips

- Hot air exceeding 40 deg. C.

- Large amount of liquid,

- Substances that remarkably accelerate rusting of metals or aging of plastics

・This product should not be used in an atmosphere which contains chlorine, sulfuric or fluorine gasses, oxalic acid, xylene, or methyl tetrachloride and the like.

・Do not use this product in a corrosive atmosphere.

・Tampering or repairing the product should be strictly avoided. Please contact us for repairing service.

・Do not operate MISTCATCH uncovering its electric part.

・Indoor use only. The altitude of the site of use should be lower than 1000 m.

・The site of use should be free from vibration or impact.

・Do not use this product in a narrow closed space.

・Make sure that the packaging is not damaged on delivery.

・Use this product within the temperature range from 0℃ to +40℃ and humidity range from 10 to 80%RH (no condensation).

・Impact, vibration or excess load should be avoided during transportation. Dismount MISTCATCH from machinery when moving it.

・Precision apparatuses should not be arranged near the exhaust port where fine particles may fall on.

・Service interval may vary depending on the amount or constituent of particles inhaled.

- Ignition sources and fire sparks generated in machine processing,

- Flammable substances such as gasoline, thinner, benzin, kerosene and others as well as oil and cleaning liquid with an ignition point 80 degrees C or below,

- Explosive substances such as aluminium, magnesium and titan as well as materials ridden with those substances,

- Flammable liquid, mist and materials ridden with these substances,

- Corrosive and adhesive substances and hazardous gas or air with a lot of unusual substances

- Large amount of dust or cutting chips

- Hot air exceeding 40 deg. C.

- Large amount of liquid,

- Substances that remarkably accelerate rusting of metals or aging of plastics

・This product should not be used in an atmosphere which contains chlorine, sulfuric or fluorine gasses, oxalic acid, xylene, or methyl tetrachloride and the like.

・Do not use this product in a corrosive atmosphere.

・Tampering or repairing the product should be strictly avoided. Please contact us for repairing service.

・Do not operate MISTCATCH uncovering its electric part.

・Indoor use only. The altitude of the site of use should be lower than 1000 m.

・The site of use should be free from vibration or impact.

・Do not use this product in a narrow closed space.

・Make sure that the packaging is not damaged on delivery.

・Use this product within the temperature range from 0℃ to +40℃ and humidity range from 10 to 80%RH (no condensation).

・Impact, vibration or excess load should be avoided during transportation. Dismount MISTCATCH from machinery when moving it.

・Precision apparatuses should not be arranged near the exhaust port where fine particles may fall on.

・Service interval may vary depending on the amount or constituent of particles inhaled.