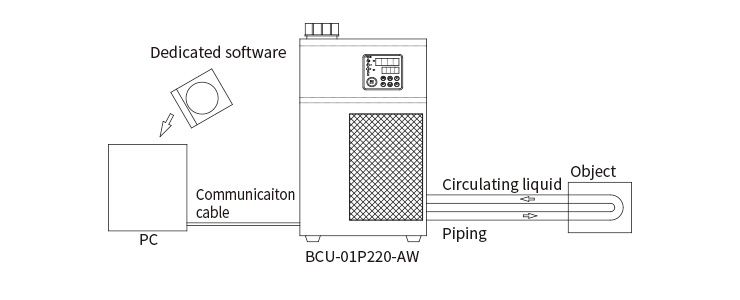

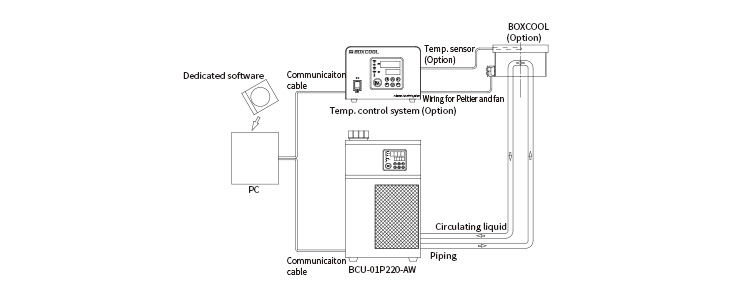

Constant temperature water circulator

Constant temperature water circulator using thermoelectric technology.

Keeps object's at constant temperature by controlling temperature of water, ethylene glycol and other circulatory liquids

Keeps object's at constant temperature by controlling temperature of water, ethylene glycol and other circulatory liquids

Features

| Environment of use | Cooling method | Heat dissipation | Function | |

| Indoor | Thermoelectric | Air cooling | Display | Wide range of supply voltages |

・Application For temperature control of dispensing liquid, medical-care equipment, laser marker, laboratory equipment, wafer production line, LD printer, etc.

Certificates/Approvals

| EU RoHS | China RoHS | CE | UL | CSA | PSE |

Model/Specifications

| Model | BCU-01P220-AW | |

| Cooling method | Fan-cooled thermoelectric cooling | |

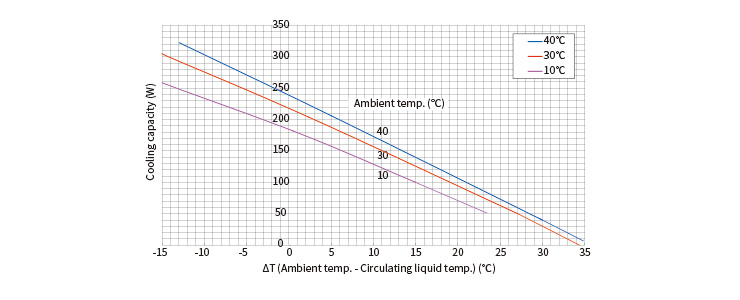

| Cooling capacity(*1) | 220W | |

| Heating capacity(*1) | 500W | |

| Rated voltage (50/60Hz) | Single phase, 100-240 VAC | |

| Max. power consumption | 600VA | |

| Liquid circulation system | Hermetically sealed circulaiton | |

| Circultion fluid(*4) | Ethylene glycol of 30% or less dilute concentraion(*2)Purified water (ion-exhange water)(*3) | |

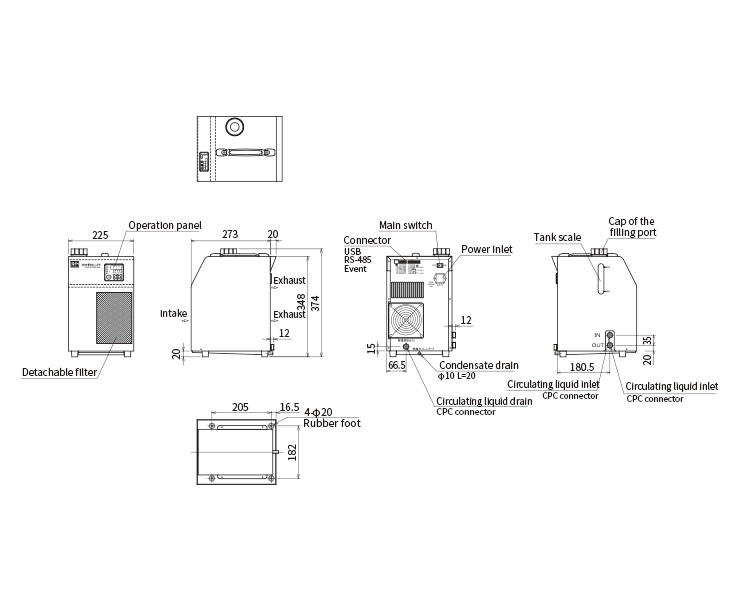

| Pipe connection | CPC coupling (supplied with the product Outer diameter of nippleØ9.5 mm) | |

| Tank capacity | 500ml(MAX) | |

| Pumping rate(*5) | Approx. 3L/min | |

| Pump head(*5) | Approx. 7.5m | |

| Temperature regulating method | PID control with auto-tuning function | |

| Control method | Polarity reversion type Linear voltage control | |

| Internal temperature sensor | Resistance temperature detector JIS Pt100/JPt100 3-wire type | |

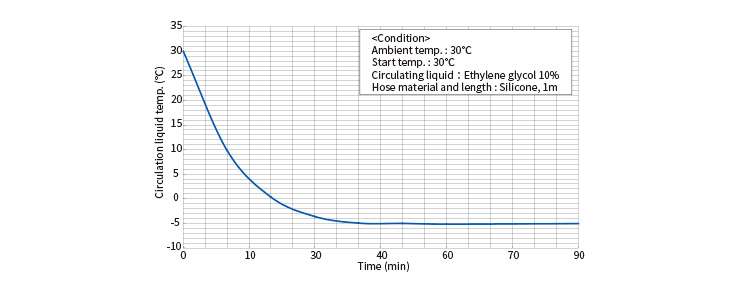

| Temperature setting range(*6) | -10℃ to +40℃ | |

| Display accuracy | ±0.1℃ | |

| Display resolution | 0.1℃ | |

| Temperature control accuracy | ±0.03℃ | |

| Working temperature | 0 to +40℃ | |

| Working humidity | Max. 80%RH, free from condensation | |

| External input/output | Analog output (0-10V) (*7)Alarm contact output (100VAC 1.0A/24V DC 1.0A)1 point Event contact ouput (100V 1.0A/DC24V 1.0A) 1 point communicaiton:RS-485 1point communication:USB 2.0 1 point |

|

| Safeguard | Fuse <250VAC 10A> (double protection on primary side) Alarm buzzer self diagnosing Detection of Upper temperature limit error/Lower temperature limit error/Cooling block temperture error/Heat dissipation fin temperature error/Thermoelectric power supply error/Decrease in circulation liquid flow |

|

| Noise | Max. 57dB(A) | |

| Conformity to standards | Environment | RoHS |

| Dimensions (mm) | W225×H374×D273 | |

| Weight(*8) | 12.0kg | |

*1 Nominal values at +30℃ ambient temperature

*2 Use a liquid which specific gravity is less than 1.0 and viscosity is less than 10 cp. Use of a thickened liquid can stop the pump.

*3 Specific resistance of circulation liquid should not exceed 0.1MΩ・cm. Failure to this can lower the pump life significantly.

*4 Please consult us if you hope to use other liquids.

*5 Value when the inlet and outlet of circulation liquid are directly connected with a pipe of 6.5 mm inner diameter and 1.0 m long. It decreases by load.

*6 Attention should be given not to ice up the circulation liquid when BOX CHILLER is used with setting less than 0℃. Failure to this can lead to the alarm "Decrease in circulation liquid flow".

*7 Analog output : Load impedance 100 kΩ or more

*8 Value not including circulation liquid

*2 Use a liquid which specific gravity is less than 1.0 and viscosity is less than 10 cp. Use of a thickened liquid can stop the pump.

*3 Specific resistance of circulation liquid should not exceed 0.1MΩ・cm. Failure to this can lower the pump life significantly.

*4 Please consult us if you hope to use other liquids.

*5 Value when the inlet and outlet of circulation liquid are directly connected with a pipe of 6.5 mm inner diameter and 1.0 m long. It decreases by load.

*6 Attention should be given not to ice up the circulation liquid when BOX CHILLER is used with setting less than 0℃. Failure to this can lead to the alarm "Decrease in circulation liquid flow".

*7 Analog output : Load impedance 100 kΩ or more

*8 Value not including circulation liquid

BCU-01P220-AW

Capacity

Cooling : 220W Heating : 500W

A complete set of supply

BOX CHILLER : 1 unit Outer diameter of nipple for CPC coupling Ø 9.5mm: 3 pcs.

Conenctor for RS485 6P : 1 pc. Power cord 3 m long : 1 pc. Instruction manual : 1 copy

Conenctor for RS485 6P : 1 pc. Power cord 3 m long : 1 pc. Instruction manual : 1 copy

Maintenance parts

| Detachable filter for replacement |

| BCF-S4 (1 pc) |

Dedicated software

Dedicated software (download free) enables operation and data storage by PC.

Cautions

・Do not use this product in a place where flammable or corrosive gasses, oil fume or any matters that can destroy insulation generate or permeate.

・The site of use should be free from vibration and impact.

・Electrical works required for installation of this product should be done only by professionals or qualified personnel.

・Do not use other liquids than specified in the instruction manual.

・Do not overfill the tank during shutdown. It may lead to overflow depending on operating condition.

・If the product is carried with holding its handle, keep a shock load away from the handle.

・Use this product on a level surface.

・Place BOX CHILLER well away from surrounding walls or other goods.

・Do not put things on the product or apply impact on it.

・Never disassemble or tamper the product.

・Make sure that the packaging is not damaged on delivery. Any packaging damage can lead to breakdown of the product. Please contact us immediately if any damage is found.

・The site of use should be free from vibration and impact.

・Electrical works required for installation of this product should be done only by professionals or qualified personnel.

・Do not use other liquids than specified in the instruction manual.

・Do not overfill the tank during shutdown. It may lead to overflow depending on operating condition.

・If the product is carried with holding its handle, keep a shock load away from the handle.

・Use this product on a level surface.

・Place BOX CHILLER well away from surrounding walls or other goods.

・Do not put things on the product or apply impact on it.

・Never disassemble or tamper the product.

・Make sure that the packaging is not damaged on delivery. Any packaging damage can lead to breakdown of the product. Please contact us immediately if any damage is found.